| Unit Price: | USD 50000.0000 / Set/Sets |

|---|---|

| Payment Type: | T/T |

| Min. Order: | 30 Set/Sets |

Additional Info

Transportation: Ocean

Port: Shanghai China

Product Description

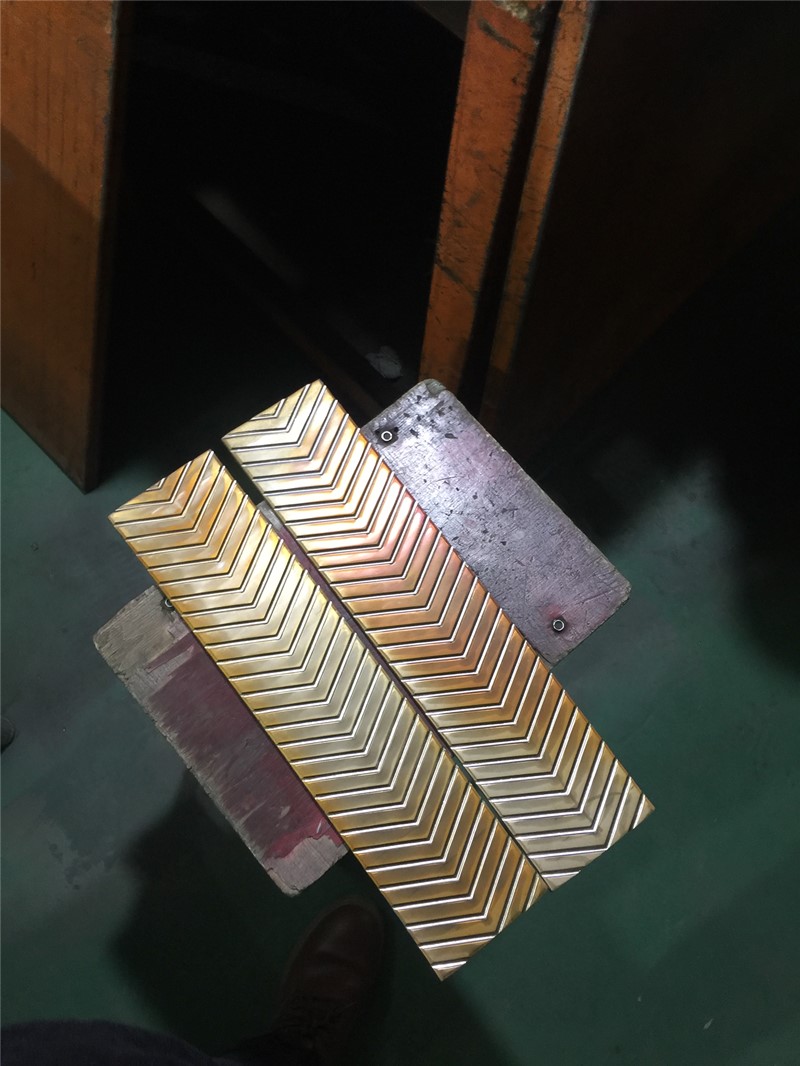

The stainless steel continuous bright annealing furnace is an ideal annealing equipment for steel pipe, stainless steel pipe, alloy steel pipe, copper pipe and copper material industry.

The equipment is manufactured in strict accordance with the production process and technology.Suitable for non-ferrous metal industry, copper industry, and other bright heat treatment.It is the key component adopts the import, its waste all USES the homebred high quality material.Strictly guard the quality, its performance and foreign products have the same level.The drive adopts idler synchronous drive, variable frequency speed regulation, stable and reliable.The furnace is equipped with a strong stirring fan, the electric heating elements are arranged reasonably, and the temperature and atmosphere in the furnace are evenly distributed

The frame of annealing furnace is welded by various steel sections, the frame is made of channel steel as the main beam, the coaming is made of cold sheet, and the annealing furnace is made by trolleyThe main beam is made of channel steel, and the bottom plate and front and rear end plates are made of middle plate.Annealing furnace drive part: trolley drive adopts motor, reduction gear through the chain to drive the front of a group of driving wheels. The furnace door drive adopts the combination of worm gear reducer and motor for electric lifting.Sealing: the cabinet and furnace body are sealed with labyrinth structure, and the two sides of the cabinet are equipped with automatic sand sealing device. The furnace door seal adopts raceway type pressing and spring pressing automatic mechanism to seal the furnace body part adopts high quality firebrick structure to ensure the sealing of the furnace chamber. High aluminum bricks are used in the compression part of the trolley.Annealing furnace combustion system: several nozzles are installed on both sides of the oil furnace, and the heat flow circulates in the furnace to ensure the uniformity of the furnace temperature. Automatic and semi-automatic models can be selected as required.